Der 11. Unternehmerinnen- und Gründerinnentag stand in diesem Jahr unter dem Motto “Frauen. Unternehmen. Zukunft.” In diesem Rahmen wurden am 17. Mai 2018 die “Unternehmerin des Landes Brandenburg” und die “Existenzgründerin des Landes Brandenburg” 2018 in der Schinkelhalle in Potsdam ausgezeichnet. Insgesamt wurden 90 Bewerbungen eingereicht. Aus der Uckermark bewarben sich die Firmen A&W Apparate & Wärmetauscherbau GmbH sowie die Sprachschmiede Schwedt Braun & Braun um einen Preis. Unter die Top 10 kam die A&W Apparate & Wärmetauscherbau GmbH aus Schwedt und wurde mit einer Nomienierung für den Preis der “Unternehmerin des Jahres 2018” ausgezeichnet. Brandenburgs Arbeitsministerin Diana Golze und Wirtschaftsminister Albrecht Gerber zeichneten die Preisträgerinnen aus.

Image Archives

THCONNECT in Wildau - we will be back

The central concern of THCONNECTis to keep skilled workers in our region, toestablish an early contact between potential employers and students as well as toshow development opportunitis in local companies. We were exited about the organization of this fair and in numerous discussions with students and professors we took the opportunity to our company.

THCONNECT 2017 in Wildau - A&W is on site

In order to preserve the expertise in Uckermark and to make thze location Schwedt palatable to young engineers, for the first time A&W did participate at the THCONNECT fair of the Fachhochschule Wildau on November 9, 2017 and answers the questions of the students. In addition to the possibility of a bachelors theses.

November 2017 - Three years of successful business

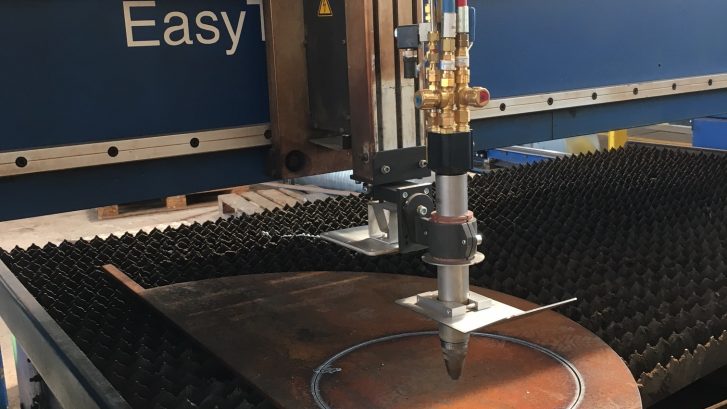

Since several weeks our last investment – a CNC-controlled autogen/plasma cutting equipment – is in operation and does cover more than just the internal needs of parts for the heat Exchangers and pressure vessels to be manufactured. also this equipment secures orders for A&W as contact manufacture for regional companies. Att present there is a large inquiry for plasma cutting parts underexamination.

Nationalparklauf Schwedt 2017 - A&W at the company relay race

Our A&W employees also keep fit and have been very successful in participating in the first Schwedt company relay race with a mixed team. Being the 2nd mixed and the 8th best of 19 relay teams in total makes us proud and satisfied at the same time. For next year, two relay races are already in planning and our team would like to be one of the medal winners.

A&W puts a new plasma cutting equipment into operation

Robust and reliable technology for large sheet thickness ranges

Our new dry plasma cutting machine offers highest reliability, a clean cut quality and a hight cutting speed within a sheet thickness range of 3 to 80 mm. An additionally gas cutting head offers the capability to process plates up to 200 mm sheet thickness.

The advantages of plasma cutting over gas cutting are mainly the up to four times highter cutting speed and the lower heat distortion because of the hight energy density. In addition, plasma cutters can cut nearly all type of metal, while gas cutting is mainly limited to carbon steels.

Automatic welding and large-scale cladding

New Investments at A&W

for more flexibility and to extend of our offering as well as to meet the hight qualityexpectations of our customers, in 2nd half of 2016 our machinery was expandet by the following important investments:

Cladding add-on (according to the electro-slag method)

With the new additional tool for our submerget are welding machine large surfaces can now be plated – eg. tube sheets or flange sealing strips or inner surfaces of pressure equipment. The electro- slag process promises uniform, quality-appropriate cladding and is independent of the type of welding consumable. The work samples meet allrequirements of the AD2000-W8.

Orbital stations from POLYSOUDE

Now two orbital stations make it possible to automatically weld.in tube-tubesheet connections. This technology promises an absolutely uniform pipe welding with hight quality, wich is absolutely suitable for X-rays and guarantees a zero failure ratio. Working withtwo equivalent orbital stations in pralle also enables a rapid finish of the tube welding and thus an optimized production time.

Schweißnahtvorbereitung mit dem “MiniMil”-Fräsautomat

automatische Rohreinschweißung

A&W again exhibitor at INKONTAKT 2017

INKONTAKT-fair announces A&W as 100th exhibitor

There was an innovation at INKONTAKT this year. The fair also wants to establish itself as a job exchange. A&W was also interested in this new opportunity: “We are looking for companies to offer our drilling and milling capabilities but of course we are always looking for good specialists and apprentices,” says CEO Katrin Wallura.

Economic development as a guest

Industrial plant construction in Schwedt

Steffen Kammradt from the Brandenburg Economic Development Corporation (r.) visited the young company ‘A&W Apparate und Wärmetauscher GmbH’ at Schwedt and spoke to the CEO Katrin Wallura.